Ceramic 3D Printing and Metal Casting Combine to Make Complex Parts

Summary

TLDRAristo Cast in Almont, Michigan is innovating investment casting with the integration of 3D printing technology. Their P.I.C.S. process utilizes 3D printed ceramic shells to create intricate metal parts with complex internal geometries. This method allows for the production of detailed components from widely available alloys at potentially lower costs compared to traditional additive manufacturing. The process involves cleaning, sintering, and dipping the shells into ceramic slurry before pouring, offering a promising blend of modern and classic manufacturing techniques.

Takeaways

- 🌐 Metal additive manufacturing enables the creation of complex internal part geometries that are unattainable with traditional methods.

- 🔍 Existing processes like investment casting may be more capable than previously thought when combined with 3D printing technology.

- 🏭 The video is set at Aristo Cast in Almont, Michigan, where they are exploring the use of 3D printing to aid in investment casting.

- 📈 Aristo Cast utilizes a P.I.C.S. (Printed Investment Casting Shell) process to enhance their casting capabilities.

- 🔄 The P.I.C.S. process involves 3D printing ceramic shells, which allows for intricate and curving internal geometries in the components.

- 💡 Components made with this process can be created from widely available alloys, potentially reducing costs compared to other metal additive manufacturing processes.

- 🧼 After 3D printing, the ceramic shells undergo a cleaning process with isopropyl alcohol and a soak to remove loose slurry.

- 🔥 The shells are then sintered, a heat treatment process that increases the strength and durability of the ceramic material.

- 🔄 The ceramic shells are attached to a sprew, a tree-like structure that organizes multiple parts for the casting process.

- 🌊 The sprew assembly is dipped into a ceramic slurry, which is the same material used in the 3D printing of the shells, to prepare it for the pour.

- ⏱️ The entire build of P.I.C.S. shells takes approximately 10 hours, highlighting the efficiency of the process.

Q & A

What is metal additive manufacturing capable of achieving?

-Metal additive manufacturing is capable of achieving complex, internal part geometries that no other process can achieve.

How does the 3D printing process mentioned in the script differ from traditional methods?

-The 3D printing process mentioned in the script aids investment casting by using ceramic shells, allowing for intricate and curving internal geometries of components.

Where is the location of Aristo Cast?

-Aristo Cast is located in Almont, Michigan.

What is the P.I.C.S. process?

-P.I.C.S. stands for Printed Investment Casting Shell, a process that involves 3D printing ceramic shells for use in investment casting.

What material is used for 3D printing in the P.I.C.S. process?

-Ceramic is the material used for 3D printing in the P.I.C.S. process.

What is the significance of the Admatec system mentioned in the script?

-The Admatec system is the 3D printing setup used to create the ceramic shells for the P.I.C.S. process.

What alloys are used in the P.I.C.S. process?

-The alloys used in the P.I.C.S. process are widely available alloys commonly used in casting.

How does the P.I.C.S. process potentially reduce costs?

-The P.I.C.S. process can potentially result in an intricate metal part at a lower cost than is often possible with traditional additive manufacturing processes in metal.

What happens to the 3D printed ceramic shell during the process?

-The 3D printed ceramic shell is leached out to be removed.

How long does it take to build P.I.C.S. shells?

-It takes about 10 hours to build P.I.C.S. shells.

What are the steps taken after 3D printing the shells in the P.I.C.S. process?

-After 3D printing, the shells are cleaned with isopropyl alcohol, soaked for loose slurry removal, and then sintered.

How is the final assembly prepared for the pour in the P.I.C.S. process?

-The ceramic shells are attached to a sprew, and that assembly on the sprew is then dipped into a ceramic slurry to prepare it for the pour.

Outlines

🏭 Innovations in Metal Additive Manufacturing

This paragraph discusses the capabilities of metal additive manufacturing, particularly in achieving complex internal part geometries. It highlights the potential of existing processes, such as investment casting, to be enhanced by 3D printing technology. The narrative takes us to Aristo Cast in Almont, Michigan, where experiments are being conducted on an aid to investment casting using 3D printed ceramic shells. The P.I.C.S. (Printed Investment Casting Shell) process allows for intricate and curving internal geometries of components made from widely available alloys used in casting. The result is the possibility of producing complex metal parts at a lower cost compared to traditional additive manufacturing processes. The process involves 3D printing ceramic shells, which are then leached out, cleaned with isopropyl alcohol, soaked for loose slurry removal, and sintered. The shells are attached to a sprew, dipped into a ceramic slurry, dried, and finally prepared for the pour.

Mindmap

Keywords

💡Metal additive manufacturing

💡3D printing

💡Investment casting

💡Aristo Cast

💡P.I.C.S. process

💡Ceramic shells

💡Accessible widely available alloys

💡Lower cost

💡Leaching

💡Sintering

💡Sprew

💡Pour

Highlights

Metal additive manufacturing can achieve complex, internal part geometries that other processes can't.

Existing processes might be more capable than previously thought, thanks to advancements in 3D printing.

The metal part discussed was not 3D printed but was made through investment casting.

Aristo Cast in Almont, Michigan, is experimenting with an aid to investment casting using 3D printing.

The P.I.C.S. process, or Printed Investment Casting Shell, is a method that utilizes 3D printed ceramic shells.

The 3D printed ceramic shells allow for intricate, curving internal geometries of components.

These components can be made from widely available alloys used in casting.

The result of this process could be intricate metal parts at a lower cost than traditional additive manufacturing processes.

The 3D printed ceramic shell is leached out to be removed, which is a crucial step in the process.

The P.I.C.S. shells' build took approximately 10 hours, showcasing the efficiency of this method.

After 3D printing, the shells are cleaned with isopropyl alcohol, emphasizing the importance of post-processing.

Loose slurry removal involves soaking the shells in a tank for an extended period.

Sintering is the next step after cleaning, which consolidates the ceramic material.

The ceramic shells are attached to a sprew, which is a necessary step for the assembly process.

The assembly on the sprew is dipped into a ceramic slurry, which is the same material used in 3D printing.

Once the slurry dries, the component is ready for the pour, indicating the final preparation stage.

This process combines the strengths of 3D printing and traditional casting to create more cost-effective and complex metal parts.

Transcripts

Metal additive manufacturing is capable of achieving complex

internal part geometries no other process can achieve, sort of.

Some of those existing processes might be more capable than we think thanks to 3D printing.

This was not 3D printed, this metal part.

This component was investment cast.

I'm at Aristo Cast in Almont, Michigan.

Aristo Cast is experimenting with an aid to investment casting using 3D printing.

Using 3D printing of ceramic. Through their P.I.C.S.

process, Printed Investment Casting Shell,

Ceramic Shells 3D printed on this system from Admatec

allow for complicated, intricate, curving internal geometries of components

made from accessible widely available alloys used in casting.

The result potentially is an intricate metal part at lower cost

than is often possible with additive manufacturing processes in metal.

The 3D printed ceramic shell is leached out to be removed.

Here are other steps in the process.

What the process looks like.

This build of P.I.C.S.

shells took about 10 hours.

After 3D printing, the shells are cleaned with isopropyl alcohol.

They are also soaked in a tank for quite a while for loose slurry removal.

Then comes sintering.

The ceramic shells are then attached to a sprew.

That assembly on the sprew is then dipped into a ceramic slurry.

The same ceramic used in 3D printing.

It dries, then it's ready for the pour.

5.0 / 5 (0 votes)

A Better Computer Fan - Sometimes: Cross-Flow Meshless AIO Case Benchmarks & Review

We made a real DOGDAY Animatronic!

Your PC Can Look Like THIS Now!

EXTREME KITCHEN RENOVATION EP 5 | Designing Our Custom Cabinetry

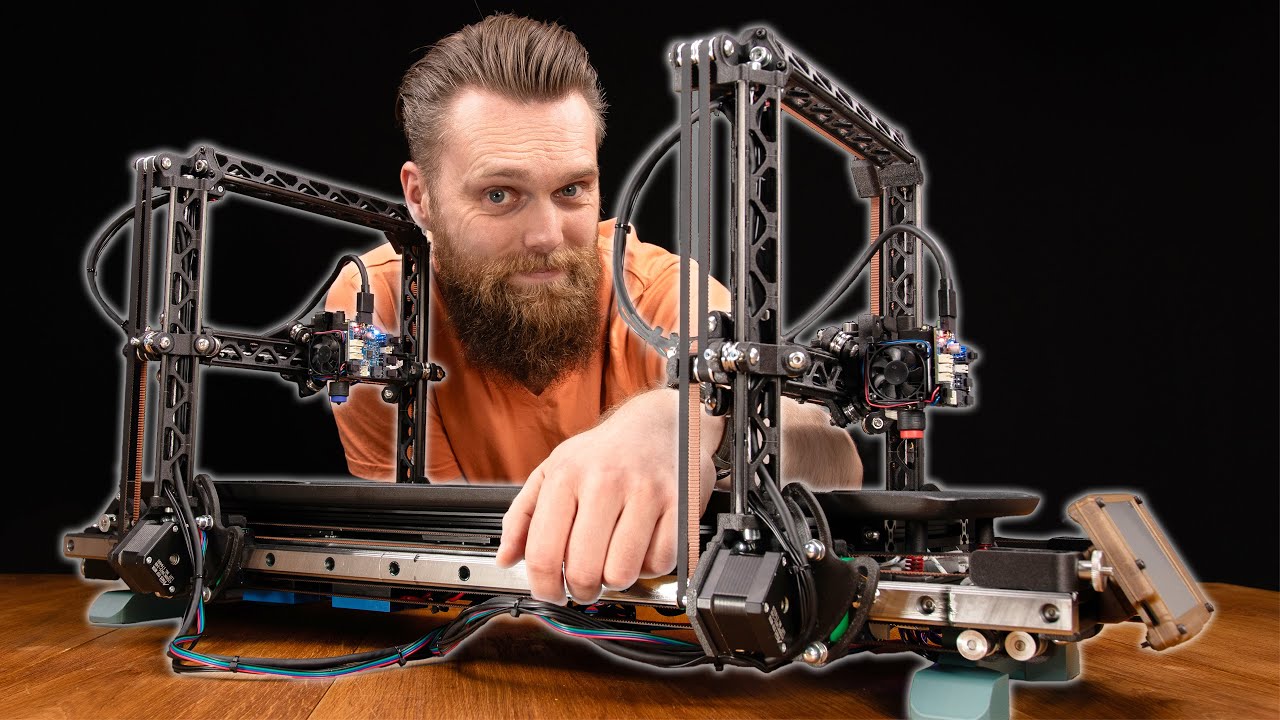

I built a 6-axis 3D printer that could be groundbreaking!

DRIVING MARCUS RASHFORDS WRECKED ROLLS ROYCE FOR THE FIRST TIME