Excavator and driveway maintenance

Summary

TLDRThe video script details a meticulous process of maintenance and repair work on various machines, including an air compressor, a Cummins engine, and an excavator. The operator emphasizes the importance of tracking oil changes and maintaining equipment, such as replacing damaged O-rings and ensuring proper fitting connections. The narrative also includes a creative solution of repurposing parts from different sources to fix the machinery. The video concludes with the satisfaction of completing the tasks and readiness to tackle new jobs, highlighting the operator's expertise and dedication to keeping the equipment in optimal condition.

Takeaways

- 📝 Effective oil change tracking can be achieved by writing the date and details directly on the machine.

- 🔇 The air compressor is notably quiet, indicating a well-maintained or high-quality piece of equipment.

- 🔧 Missing or loose fittings can be a source of irritation and should be promptly addressed to prevent further issues.

- 🛠️ Hoses and O-rings should be inspected regularly for damage, as seen with the damaged O-ring causing a leak.

- 🔄 The use of non-standard parts, like high-pressure O-rings from a different source than Harbor Freight, may be necessary for certain repairs.

- 🔋 Batteries and starters are critical components that, when replaced or repaired, can significantly impact the performance of machinery.

- 🚜 Practical problem-solving, such as creating a starter from two different ones, demonstrates resourcefulness in maintenance tasks.

- 🏠 Keeping work areas organized, like ensuring an open aisle for access, is important for efficiency and safety.

- 💡 Regular inspection and maintenance of filters can extend the life and improve the performance of equipment.

- 🚨 Even experienced machinery like an excavator can require ongoing upkeep to maintain its efficiency and effectiveness.

- 🔄 The process of troubleshooting and repair is an iterative one, often involving multiple steps and adjustments.

Q & A

What is the speaker's method for keeping track of oil changes?

-The speaker writes the oil change record directly on the machine in a visible place for the operator to see and updates it every time an oil change is performed.

What specific date and number of hours does the speaker mention regarding the air compressor?

-In May 2015, the air compressor had 6960 hours on it.

What issue was the speaker bothered by with the air compressor?

-The speaker was bothered by a missing fitting on the air compressor that was loose.

What type of fittings were used on the air compressor and what was the issue with them?

-The fittings were 1/8 NPT, and the issue was that they seemed to mesh properly, but one was bigger than the other, indicating a potential problem.

How did the speaker address the issue with the hoses?

-The speaker noticed that some hoses looked old and decided to change them, specifically mentioning five new hoses.

What was the problem with the O-ring that the speaker discovered?

-The O-ring was damaged, which was causing a leak.

What type of O-rings did the speaker use for the repair and where were they sourced from?

-The speaker used high-pressure O-rings that were not from Harbor Freight for the repair.

What was the issue with the grease on the machine?

-The machine was not taking grease, but after moving the pin, it started to take grease, indicating that the issue was resolved.

What did the speaker do with the starter of the Cummins engine?

-The speaker ordered a replacement starter from a Dodge pickup with a Cummins engine because it looked the same, but it turned out to be a mirror image of what was needed. The speaker then made one starter out of two.

What was the speaker's strategy for organizing the workshop space?

-The speaker wanted to keep an aisle open so they could walk through and decided to park the forklift inside a bay with the doors removed to ensure access.

What was the condition of the Hitachi excavator?

-The Hitachi excavator was working well and has been in use for over 12 years. The speaker was preparing it for two upcoming jobs and made some repairs and adjustments.

Outlines

📝 Maintenance and Tracking

This paragraph discusses the importance of keeping track of oil changes and maintenance tasks. It mentions writing the oil change dates directly on the machine in a visible spot for the operator. The speaker reflects on a past oil change in May 2015 and shares their method of continuously updating the information. Additionally, the speaker talks about the quietness of their air compressor and the issue with a loose fitting, which is identified as a 1/8 NPT thread. The discussion then shifts to noticing hoses and the need to replace them, emphasizing the importance of timely maintenance.

🔧 Air Compressor Fittings and Hoses

The speaker continues the conversation about air compressor maintenance, focusing on the fittings and hoses. They describe the issue with a fitting that was loose and how it did not match the others in terms of thread size. The speaker then observes hoses and decides to change one that looks old but is still functional. The attention then shifts to a damaged O-ring, which is identified as the cause of a leak. The speaker emphasizes the use of high-quality O-rings and the difficulty of replacing them, especially those not from Harbor Freight.

🚜 Forklift Maintenance and Battery Issues

This paragraph covers the speaker's experience with a forklift. They discuss the challenges of replacing a starter from a Cummins engine and the cost-effective solution of using a part from a Dodge pickup truck. The speaker also talks about the need to keep the forklift inside and the importance of keeping an aisle clear for access. The paragraph concludes with the speaker's intention to use the forklift in a bay and the realization of the necessity to remove the doors for easy access.

🔧 Grease Application and Battery Testing

The speaker addresses a problem with a machine not taking grease and shares a simple solution of moving a pin. They observe that the machine starts taking grease after this adjustment, indicating that the issue was resolved. The speaker also discusses testing a battery and finding that the old one did not perform poorly. The focus is on troubleshooting and fixing issues to ensure the machinery operates efficiently.

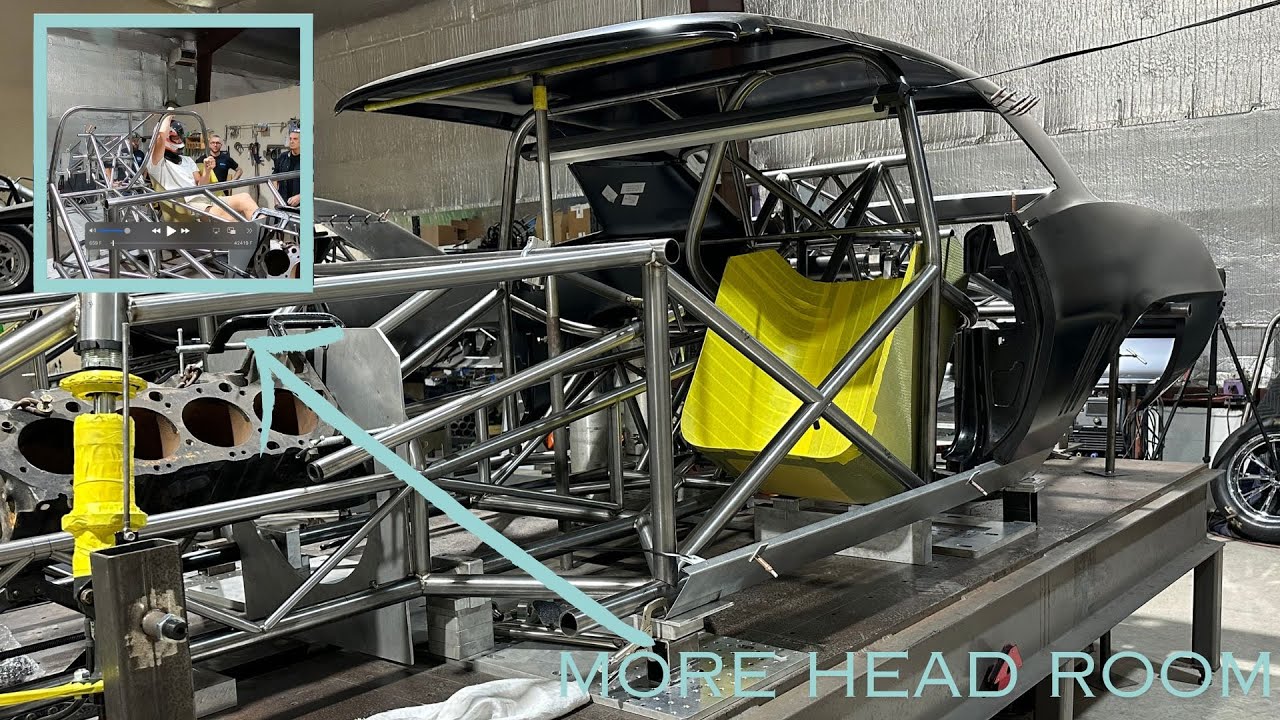

🚜 Starter Replacement and Excavator Maintenance

This paragraph details the process of replacing a starter in an excavator and the challenges faced when the replacement part turns out to be a mirror image of what was needed. The speaker creatively combines two starters to create a functional one. They also discuss the importance of the excavator's performance and the decision to use it on two upcoming jobs. The speaker concludes by expressing satisfaction with the completed maintenance and readiness to move on to other tasks.

🏗️ Excavator Performance and Material Tracking

The speaker evaluates the performance of their Hitachi excavator, which they have owned for over 12 years. They discuss the excavator's ability to effectively break up shale into gravel and the minor issues with the ground caused by pipe installation. The speaker also talks about the excavator's efficiency in tracking material and their plan to use it on two jobs after completing necessary maintenance. The paragraph ends with the speaker's satisfaction with the work done and a readiness to tackle other projects.

Mindmap

Keywords

💡Oil

💡Coolant

💡Air Compressor

💡Fittings

💡Hoses

💡O-rings

💡Forklift

💡Excavator

💡Maintenance

💡Workshop

💡Repair

Highlights

Oil and coolant levels are checked and verified to be at the correct levels, ensuring the proper functioning of the equipment.

A practical method for tracking oil changes is suggested, which involves writing the information directly on the machine for easy visibility and reference.

The quietest air compressor is identified, with a specific mention of the model and the number 6960.

A missing fitting is discovered and addressed, highlighting the importance of regular inspections and maintenance.

The issue with the 1/8 NPT fitting is discussed, emphasizing the need for proper fitting and thread matching.

Observation of hoses and the decision to replace them showcases proactive maintenance practices.

The discovery of a damaged O-ring leading to a leak is mentioned, emphasizing the critical role of seals in preventing fluid loss.

The use of high-quality O-rings from a reputable source is highlighted, indicating a preference for durability and reliability.

A practical tip for applying grease is shared, noting that sometimes simply moving a pin can help in the process.

The process of replacing a starter from a Cummins engine is described, demonstrating resourcefulness and adaptability.

A creative solution is found by combining two starters to create one that fits the specific needs of the equipment.

The importance of keeping the work area organized and accessible is emphasized, with a focus on maintaining an open aisle for safety.

The functionality and performance of a filter are assessed, highlighting the need for regular checks and replacements.

The efficiency of an excavator in breaking up shale into gravel is noted, showcasing the machine's capabilities.

The Hitachi excavator's reliability and longevity are praised, with a mention of its 12-year service.

The completion of maintenance tasks is acknowledged, signaling readiness for the excavator to be deployed on two jobs.

Transcripts

Oil is right where it should be

Coolant is right there too

Ok, got it

You guys being good?

That's my favorite way to keep track of oil changes.

Just write it right on the machine somewhere where the operator can see it.

And every time you do it, just keep writing.

In 5/2015 I had 6960

This is the quietest air compressor

I'm missing a fitting up there

and this is bugging me.

It was loose

these are 1/8 NPT.

But even though these threads seem to mesh

properly,

See, that one is bigger

Okay, so it's not that

definitely not.

I'm noticing hoses

that look like that.

So let's just change this now

there's my one to hand to the shop

That one's been changed.

And that one,

It's old, but it's not.

That one's all right.

That line right there, look at that.

five new hoses

Is this O-ring damaged?

Yes, it is

Okay.

That's why that was leaking

O-ring is damaged here

These are high pressure O-rings

They are not from Harbor Freight.

Getting these in here is difficult

Blue, get the Frisbee

Blue, what is that? Get that Frisbee

What?

It's not taking grease,

Not taking it

or sometimes just moving that

pin around is all it takes.

Yeah, it looks like it's taking grease now.

Sounds like that.

That Uncloged it.

I just put a battery in this

The old one didn't really test bad.

Okay,

That goes there

This starter was out of, this is a Cummins engine

so I ordered one out of a and the starter was like expensive

but I ordered one out of a pickup truck, you know, a Dodge pickup with a Cummins

because it looked the same and then it was like a mirror image

of what I needed it to be.

So I made one starter out of two

This is the right one.

Put that big one on

It needed a starter

Usually starters work or they don't.

But in this case, it was not strong enough

I want to keep this forklift inside

I want to put this in this bay but let me get these doors off of here

because if this parked there all the time, you won't able to get in there.

Yeah.

I'm realizing I need to keep an isle open

open, just that I can walk through against these doors here.

Thats in enough

Not tight enough, I’ll put it on “Two”

like this.

That filter looks good

See like that.

I'm not going to use that

It needs to charge longer than 5 minutes.

That ran overnight, till it ran out of gas

recently.

Put that pipe in.

That's working good But there is a few little potholes here.

All right.

Well, that looks pretty good.

That excavator always did a good job tracking on material for some reason.

I can see how that shale breaks up into nice little gravel.

This spot was only muddied up because I just put this pipe in

and some dirt kind of came up when I did it. So.

Yeah, look how that rock breaks up.

All right, well, the Hitachi is working good

This is the second excavator I've ever bought.

I've had this over 12 years now.

It's all ready.

I'm about to bring this out on two jobs,

so I just wanted to fix some stuff on it first.

We're all done here. Let's go work on something else.

5.0 / 5 (0 votes)

Most Reliable 200K Mile Car? Let's Settle This!

DRIVING MARCUS RASHFORDS WRECKED ROLLS ROYCE FOR THE FIRST TIME

WE'RE HELLCAT SWAPPING A 350Z!

I DESTROYED A ROLLS ROYCE TO REBUILD MARCUS RASHFORDS WRAITH

Cleetus McFarlands Camaro "Eagle" Gets a body!

This Oldsmobile Station Wagon Has Been Sitting for 16 Years! | Roadworthy Rescues