$500 Allis Chalmers Crawler, Sitting for Years. (Will It Run?)

Summary

TLDRIn this video, Matt from Diesel Creek brings home another Alice Chalmers HD5G track loader for just $500. Although the machine was running a couple of years ago, the steering clutches are frozen, preventing it from turning left or right. Matt attempts various methods to free the clutches, including shock loading them with a chain attached to another machine. Despite his efforts, the clutches remain stuck. Determined to get the loader operational, Matt plans to disassemble the clutch covers, pry them free, and give the entire machine a thorough service. With its strong 271 Detroit engine and decent hydraulics, this $500 purchase shows promise once the clutch issue is resolved.

Takeaways

- 🚜 The video is about recovering an old Alice Chalmers HD5G track loader that the host purchased for $500.

- 🔐 The main issue with the machine is that both steering clutches are frozen, preventing it from turning left or right.

- 🆙 After some effort, the host is able to get the machine's engine running and maneuver it into a position for loading onto a trailer.

- ⛓️ Attempts to shock load and break free the stuck clutches using chains and another machine are unsuccessful.

- 🔧 The host plans to disassemble the clutch covers and try freeing the clutch packs manually, potentially requiring removal if prying doesn't work.

- 🛠️ Despite the steering issue, the engine, hydraulics, and other components seem to be in decent working condition for the price paid.

- 🚿 Once the clutches are freed, the plan is to steam clean the machine, give it a complete service, and address any other critical issues.

- 📈 The host expresses optimism about getting the machine ready for action after the necessary repairs and maintenance.

- 👍 Viewers are encouraged to like the video and support the channel by purchasing merchandise from the host's website.

- 📝 Overall, the video chronicles the process of attempting to revive an inexpensive but promising tracked loader acquisition.

Q & A

What is the price Matt paid for this Alice Chalmers HD5G track loader?

-Matt paid $500 for this Alice Chalmers HD5G track loader.

What was the main issue with the track loader when Matt acquired it?

-The main issue with the track loader when Matt acquired it was that the steering clutches were frozen, which meant the machine could only go forward and backward but not turn left or right.

What engine powers this Alice Chalmers HD5G track loader?

-The Alice Chalmers HD5G track loader is powered by a 271 Detroit engine.

What method did Matt initially try to free up the frozen steering clutches?

-Matt initially tried to shock load the steering clutches by attaching a chain to an immovable object (the bucket of a skid steer) and driving the track loader against the chain's tension.

Why did Matt decide to steam clean the track loader before attempting further repairs?

-Matt decided to steam clean the track loader first because it was covered in grease, grime, and oil, which made it difficult to see and access the components underneath the engine.

What was Matt's plan after steam cleaning the track loader?

-After steam cleaning the track loader, Matt planned to pull it into the shop and try to free up the steering clutches. If successful, he intended to give the machine a complete service from end to end to ensure it was ready for action.

How did Matt feel about the overall condition of this Alice Chalmers HD5G compared to the previous one he worked on?

-Matt felt that this Alice Chalmers HD5G was in much better condition than the previous one he had worked on. It was not nearly as abused, beat up, or clapped out.

What did Matt say about the engine's performance when he initially started it up?

-Matt was impressed that the engine started without any ether and seemed pretty strong, pushing against the machine without bogging down or dying out.

What did Matt mention about the hydraulics on this track loader?

-Matt mentioned that the hydraulics seemed to function pretty quickly, and the cylinders weren't dumping fluid on the ground, suggesting the packings were bypassing internally but still in decent condition for his needs.

How did Matt encourage viewers to support his channel?

-Matt encouraged viewers to hit the thumbs up button on the video, as it doesn't cost them anything but helps support the channel. He also promoted purchasing merchandise from his website, dieselcreek.com, including the new heavyweight hoodies.

Outlines

🚜 Acquiring and Inspecting the Alice Chalmers HD5G Crawler

The video starts with the acquisition of a used Alice Chalmers HD5G crawler loader for $500. The host, Matt, inspects the machine, noting its better condition compared to a previous loader he worked on. However, he mentions that the steering clutches are frozen, which could pose a challenge. Matt checks the engine oil and coolant levels, observing the general condition of the machine, including the tracks and sprockets, which appear to be in decent shape.

🔧 Attempting to Start the Crawler's Engine

Matt begins the process of trying to start the crawler's 271 Detroit engine. After priming the fuel system and initially failing to get the engine running due to an issue with the fuel rack, he discovers that the fuel shut-down lever was stuck in the on position. After resolving this issue, the engine starts successfully. Matt then attempts to move the crawler back and forth to try and free the frozen steering clutches, but this effort proves unsuccessful.

🔩 Improvising to Reposition the Crawler

Unable to free the steering clutches, Matt devises a plan to reposition the crawler. He hooks a chain to the bucket and secures it to a nearby tree. By driving the crawler forward, the chain tightens and rotates the front of the machine, allowing Matt to align it with the driveway for easier loading onto a trailer. The improvised method works better than expected, and Matt successfully maneuvers the crawler into position.

⚙️ Revisiting the Crawler and Planning to Free the Clutches

Several months later, Matt returns to the crawler with the intention of freeing the stuck steering clutches. He explains that the clutch packs have become seized due to rust or friction, preventing the clutches from separating and allowing steering. Matt plans to attempt breaking the clutches free by shock-loading them, either by slamming on the brakes or hooking a chain to an immovable object and letting the crawler run into it.

🔗 Attempting to Shock-Load the Clutches

Matt hooks the crawler's bucket to the bucket of a larger machine, using the larger machine's weight as an anchor point. He then attempts to shock-load the steering clutches by reversing the crawler and letting it pull against the chain. However, after a few tugs, Matt decides that the chain setup is not suitable and decides to find a more robust cable or chain to try the shock-loading method again.

🛠️ Evaluating the Crawler's Condition and Next Steps

With the shock-loading attempt unsuccessful, Matt acknowledges that he has exhausted his tricks for freeing the clutches. He evaluates the overall condition of the crawler, noting that the engine seems strong, and the hydraulics are functioning adequately for the machine's intended use. Matt plans to steam clean the crawler, pull it into the shop, and properly disassemble and service the clutches to get the machine fully operational.

🎬 Closing Remarks and Channel Promotion

In the closing segment, Matt promotes his channel, encouraging viewers to like the video and visit his online store to support the channel. He mentions the availability of new heavyweight hoodies and provides the website link for viewers interested in purchasing merchandise.

Mindmap

Keywords

💡Track Loader

💡Steering Clutches

💡Detroit Diesel Engine

💡Ether

💡Recovery

💡Fuel System

💡Steam Cleaning

💡Clutch Pack

💡Hydraulics

💡Restoration

Highlights

The owner claims the machine was running about 2 years ago, so getting it running should not be too much of an issue, but the steering clutches are frozen.

Checking the engine oil and antifreeze levels before attempting to start the machine.

Jumping the starter with a jump pack to turn the engine over.

Priming the fuel system by bleeding the fuel line and using starting fluid (ether) to help get the engine to start.

Discovering that the fuel shut-off lever was stuck in the "on" position, preventing fuel from reaching the injectors.

Successfully starting the engine after freeing the fuel shut-off lever.

Using a chain and tree to pivot the machine 90 degrees, since the frozen steering clutches prevented turning.

Attempting to shock-load the steering clutches by attaching a chain between the machine and an immovable object (another machine).

Realizing that the chain setup was not strong enough to shock-load the clutches, and deciding to disassemble the clutch covers for manual inspection.

Assessing the overall condition of the machine, highlighting the reasonably good engine, hydraulics, and track components for the $500 purchase price.

Planning to steam clean the machine, pull it into the shop, and attempt to free the clutches, followed by a complete service if successful.

Encouraging viewers to like the video and support the channel by purchasing merchandise from the website.

Introducing the new heavyweight hoodies available on the website, which the host prefers over the previous hoodie designs.

Providing the website link (dieselcreek.com) for viewers to purchase merchandise and support the channel.

Signing off and thanking viewers for watching the episode.

Transcripts

hey everybody welcome back to diesel

Creek my name is Matt behind me just

like Britney Spears oops I Did It Again

this is another Alice chers HD 5G track

load this one also came to me for the

low low price of $500 guys for 500 bucks

I just can't turn one of these things

down they are worth more in scrap than

that this one however is not scrap it is

decidedly better than the one that we

did previous on this channel the fell I

just bought this beauty from tells me it

was running about 2 years ago so

theoretically getting it running should

not be too much of an issue but he tells

me there's bigger problems the steering

clutches are all Frozen that could prove

to be quite an issue so with the

steering clutches Frozen basically this

machine should go forward and backward

but will not turn left or right and if

you can look straight ahead pretty much

no way that you could get a trailer

backed into this thing for it to walk

straight up onto a

trailer and of course behind the machine

more trees and no way to get a trailer

into it so we're going to have to try to

get this thing fired up and then get it

spun about 90° so that we can

potentially get it loaded up onto the

trailer that is all of course provided

that this thing even starts because if

the engine doesn't start that means

we've got a loader bucket that is sunk

into the ground and that is going to add

to the complexity of this recovery so

with a little bit of luck and maybe a

little bit of

ether hopefully our little 271 Detroit

that powers this unit will fire right up

boys look at the grease on this engine

tons of debris packed down in there

around the bottom of the engine looks

like a whole belly pans just full of

stuff out of all my machines I think

this one could probably benefit from a

good steam cleaning the most but it's

that time of year where we're not going

to break out the steam cleaner it's

going to uh going to probably be wearing

this grease until spring and it is

getting colder by the minute out here

but let's go ahead and check some fluids

before we get carried away looks like

our dip sticks down in

here

uhhuh oh yeah she's got

and it's also got dirt all over the

dipstick now since I just drug it across

the track we're going to have to wipe

that off this is how you keep your boots

oiled properly just always wipe

dipsticks on

them keeps the leather very Supple

1540 don't tell my wife this is how I

clean off dipsticks

sometimes sorry our engine oil is good

let's have a gander at this

radiator oh look at this it's got some

Dodge superpower on

here what is going on with this thing oh

that's interesting there's no radiator

cap we'll just we'll just use this

thing well it's not ideal and there's

some dead bugs hiding in there but

there's antifreeze and it's green so

when I showed up here to buy this thing

the whole machine was actually covered

with a tarp which was good and he had

this Bucket over the stack which has

been nice of

him so we shouldn't have any issues with

into the engine

hopefully it's been a while I think

since she's

run that's probably the most wallered

out rain cap I think I've ever seen

too yeah everything is definitely in

much better condition on this machine

than the other one that we have so I'm

feeling good about this purchase

hopefully it just comes to freeing up

some steering clutches well that one

actually

moved we'll see what we can do here

let's try to get this thing fired up

first the fuel tank on this machine is

in slightly better condition than the

other hd5 as well these things take a

beating since they're kind of sticking

out proud back here if you know you're

working in the trees or something it's

very easy to back into a tree when

you're not paying attention dent in that

tank and it's definitely it's seen some

abuse over the years too but nothing

like the other one we have

underc Carriage is in pretty good shape

we got a good bit of rail height left

the rail height if you don't know is the

distance between this flat spot and this

guy right here so that looks about I

don't know 60% maybe the sprockets are

pretty good the sprockets still have

nice squared off teeth on them actually

the sprockets look look real

good looks like they welded some new

ones on there this is all weld here and

it's actually cut in half and rewelded

right

there idlers have also been beefed up by

the looks of it they're nice and squared

off that helps keep the

track on the

rails all in all not bad for 500 bucks I

don't think let's break out the jump

pack and see what happens So based upon

my experience with the last one it's

going to be much easier if we just go

straight to jumping on the

starter which is kind of down in here

really hard to get the camera on you can

barely fish the jumper pack underneath

the boom arm and get it over there on it

but it is possible all right I think

that this machine was originally wired

for two 6vt batteries one in each

armrest here but I just hooked 12 volts

up to one side maybe that'll work

enough get this thing cranking over if I

slide this Rod right here it should

engage the

starter

contact nothing all right that Rod Runs

up here to the operator's platform it's

actually meant to be pushed with your

foot so maybe it just needs a little

more

Jam yet all right hopefully we got our

connected right this time

contact there we go things are happening

all right so we should be ready to turn

this thing over but I know that it's not

going to start at first

because there was no fuel in the tank

the tank was nice and clean but it was

bone dry so I went ahead and dumped a

couple gallon of fuel in

it and now because the tank was empty

we're going to have to Prime the

filters so I have this line right here

open to let the fuel bleed out but it's

after the fuel pump so we're going to

have to crank the engine over to get

that to bleed out all right I'm going to

crank it you guys just holler when you

see

fuel

nothing

yet starting to get a little bit of fuel

fuel starting

to just tighten that back

up fuel should be pretty well primed

up we're going to probably have to help

it out a little bit with The Ether but

hopefully she goes here

contact uh-huh come on

kick the starter

out there we

go oh come on stay

running

h

I

H yeah it's not picking up fuel all the

way I don't know all right it rebled the

fuel system we had an air pocket that I

didn't get

before so hopefully it'll actually take

off this

time

contact come

on yeah we might need some more let me

go see if I have any

more give her another go here got some

more ether and some more

battery still not catching fuel I don't

understand I'm going to try pressurizing

the whole fuel system and force bleeding

it with

air we're getting plenty of fuel coming

out of this fitting it's not making

sense why we're not getting it up to our

injectors I might pull the valve cover

off and check it right there on the

injector see if we're getting fuel right

[Music]

there

seems to be moving

freely

all right so this should be your fuel

line coming into the injector this

should be your return line from the

injector I'm going to crank it over and

make sure we got fuel coming out of

those yep getting all kind of fuel

something about this fuel rack doesn't

seem right like we should be able to

shove these in further I think I'm going

to take the control arm off the side of

the rack and run it manually I think we

found our

issue

yep that is the fuel shut down lever and

it was stuck in the on

position there we go now we're giv full

fuel to the injectors that's what we

needed all right I'm feeling confident

that was our issue

here hopefully this thing fires right up

now I'm going to try not to even give it

any

ether all right

contact there we

go

beautiful

all right it

runs that is great news now we just need

to get it out of

here so my plan is I'm going to try to

walk it back and forth here a few times

and then we'll start trying to work on

getting these clutches to break free

maybe we can get lucky if we can get one

of them free we can get this thing on

the trailer real

easy

all right we'll put it in first gear

here should be that guy right

there and we'll engage the

clutch uh-oh shouldn't like

that there we

go

oh yeah these things tracks haven't

turned in a long

time

all right well it doesn't look like I'm

going to have any luck getting the

clutches to steer well to get this thing

out of here here's my plan I've got a

chain hooked on the side of the bucket

there and we're going to improperly use

a yankum rope so I apologize to those

guys in advance and I've got it

connected up to this tree over here and

what I'm hoping is going to happen is

I'm going to start to drive forward

everything's going to tighten up and

that'll just bring the front of the

machine right around the direction I

need it to

to point down the driveway and then I

can just walk it right up there is my My

Hope here goes

nothing he he hey it's

working

all right I'm not going to lie that

worked way better than even I expected

it

to

here's where my smart smart plan comes

to an end how do I get this unhooked

now it's under tension

still yeah not

happening

[Applause]

[Music]

well and just like that another Track

Loader

[Applause]

[Music]

[Music]

saved

[Music]

what a sweetheart this one runs a heck

of a lot better than the other one

did not nearly as abused or beat up or

clapped

out we get those steering clutches freed

up it might be a decent little

machine there we

go we made her

home okay here we are back with the hd5

a few months later and I want to try to

see if we can get these clutches freed

up today so what actually happens in

there when the clutches stick is that

the friction plates stick to the steel

plates um and basically the clutch pack

just won't separate it doesn't have any

tension on it that's holding it it's

just kind of stition or rust or whatever

it may be in there um so sometimes you

can get lucky and break those clutch

packs free by shock loading the clutches

now you can do that a couple different

ways um but you basically just pull the

clutches and disengage them and then

because you're going no matter what you

pull those and you'll still keep going

and then you can run it into a tree

stump or something hard or hook a chain

to it which is I believe what we're

going to try today and hook it to an

immovable object so that when you get to

the end of the chain it induces a shock

load into that drive line and can break

those clutches free sometimes if you're

lucky that's what I was trying to do the

day we got this thing running

by stabbing the brakes because that can

do it if they're not stuck very bad

sometimes you can just stab the brakes

really hard while you have the clutches

pulled and in our case all I did was

break the the brake linkage on that left

side so let's hook the jump pack up see

if this thing fires up and see what's

going to happen okay here we go

contact bad ground

shocked

Bo it wants to

go get a switcher over to 24 volt real

quick just to make it spin a little bit

faster I bet it goes ready

contact yeah it either goes or we smoke

our

connection come on

t

all right so the old crawler's been

warming up for a little while it's time

to see what we can do about those

steering clutches now remember both

steering clutches are frozen unlike the

other hd5 we worked on a while back so

I've got two choices when operating this

thing I can go forward or I can go

backwards I cannot steer either

direction you're just on a fixed path

so the old cabelo here is going to have

to provide the steering for us today and

I think that we're also going to use it

as the immovable object for to attach

the chain

to

all right so we got the

hd5 tethered off to the bucket of the

cabelo and if you'll notice I have all

the weight of the cabelo actually

sitting on the bucket so we're not

pulling against the Hydraulics really

all as much as uh the ground or at least

the ground is helping quite a bit I'm

not just shock loading that

boom so yeah let's back up and give her

a go

here

[Applause]

all right I'm going to hold off on this

for a second I don't like this apparatus

here I didn't even pull on it super hard

I just gave her a few tugs

and I don't like this chain I this

thing's actually pulling a bit harder

than I thought it was going to be able

to let me try to find a heavier cable or

something to put in between there chains

or cables when they snap can come up and

do some radical stuff and that's why I

have the Anchor Point uh about even with

the hitch point on the machine because

if it snaps theoretically it goes

straight you know if you have it on an

angle it can break and go uh on that

angle

a

well

guys that didn't

work that's the extent of my bag of

tricks on trying to get these clutches

freed up so unfortunately we're going to

have to dive into this thing we're going

to actually have to pull off the fuel

tank the seat all that assembly and the

top of the clutch covers there and

hopefully we can break the clutch packs

free with a pry bar or something without

to actually disconnect and remove the

clutches but if it comes to that you

know that's the next step I think we do

have a pretty good loader here though

for what a paid 500 bucks really can't

go wrong like I said at the beginning of

the video I think that it's worth more

in scrap so we have a good running 271

Detroit I was really impressed it

actually started without any ether and

it was pretty cold when I started this

the engine seems pretty strong pushing

Against the Machine here I mean it it's

spinning the track so nothing's uh

slipping the engine wasn't bogging down

or dying out I think the engine's pretty

good the Hydraulics they seem to

function pretty quickly I really can't

complain too much about them I mean the

cylinders aren't dumping fluid out on

the ground or anything I think the

packing is bypassing internally pretty

good but for what this machine is we

really can't complain about that if you

were going to take this machine and you

know use it a lot or try to restore it

or something sure we would take those

cylinders down and repack them reseal

them and all that jazz but for my

personal needs and what we're going to

do with this machine I'm not going to

worry about those cylinders they're

going to be just fine for now if they

start leaking real bad that'll be a

different story so all that being said I

think it's going to be a little bit of

time before you guys see this unit again

but when you see it we're probably going

to be steam cleaning it all off so we

can actually see what's going on

underneath the engine there cuz it is

just covered in grease and grime and oil

after that's all done I think we're

probably going to pull it into the shop

and see what we can't do about those

clutches if we get the clutches freed up

we'll give the whole thing a complete

service from end to end and uh make sure

there's nothing else critically wrong

with it I think this machine's going to

be be ready for action after that

anyways guys I think that's about where

this one's going to wrap up if you like

this video do me a big favor hit that

thumbs up button down below the video it

doesn't cost you guys a dime it really

helps out the channel helps me to keep

buying stuff like this and uh making

cool videos for you guys about it if you

guys would like to help support the

channel in a little more direct way head

on over to dieselcreek decom pick

yourself up some sweet swag over there

we just got some new heavyweight hoodies

over there at the store I really like

these hoodies I was not a big fan of the

old ones so I decided we're going to get

something better these things fit almost

like a car heart they're nice and long

uh they're definitely a better quality

hoodie for the money so if you guys are

interested in these we have a couple

different designs and a bunch of

different colors over there that's

diesel creek.com link as always is down

below but anyways that's all I got so

until the next time guys thanks for

watching I'll catch you

[Music]

later

[Music]

[Applause]

[Music]

yeah

5.0 / 5 (0 votes)

Cleaning up an Abandon Barn! (Rotting for 10+ years)

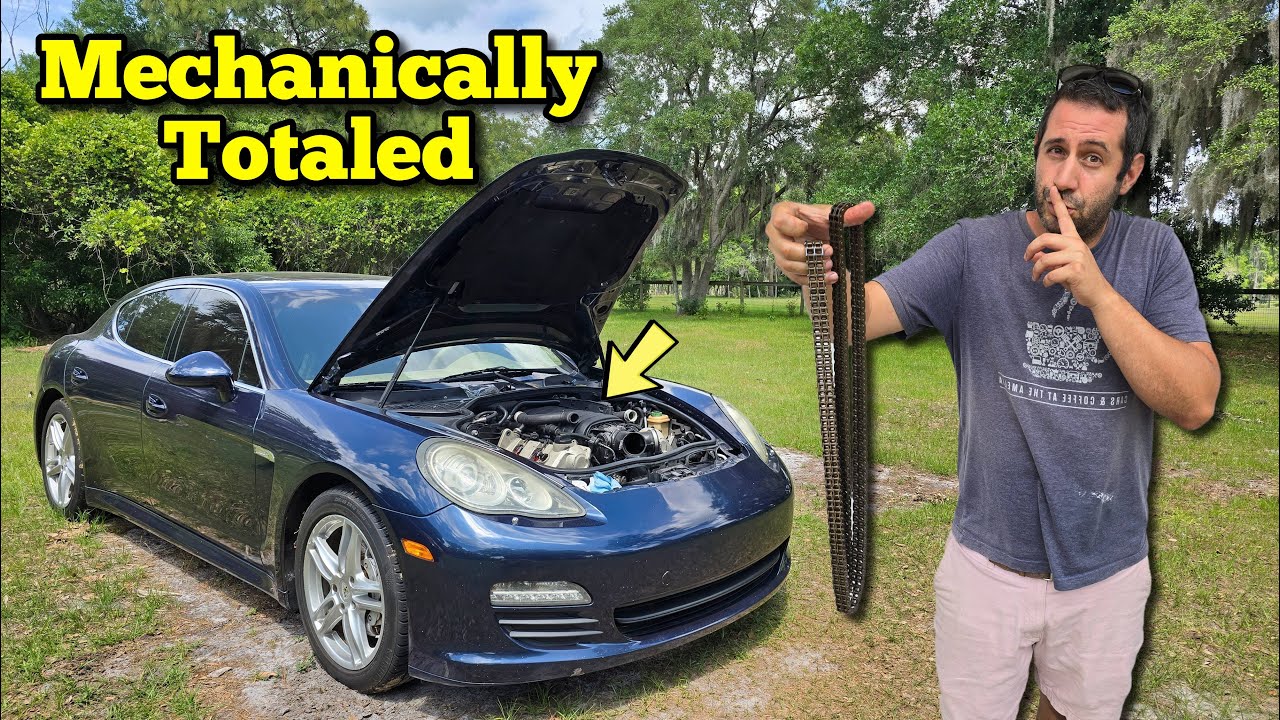

I Bought a Mechanically Totaled Porsche and Fixed it with a $200 Amazon Timing Kit

This Ford Ranger Cost a $100,000 to Build.. Not Really

We Put $5,000 Brakes on our $500 Ranger

I Bought a New Old Harley Motorcycle, Its got Problems

I Bought A Legit Freaking NASCAR